The Indian logistics market is expected to grow to about $380 billion by 2025, according to various industry experts. According to S&P, the Indian government is taking considerable efforts to raise the manufacturing sector to 25% of GDP from 17.7% by 2025. As the manufacturing sector’s growth accelerates, establishing robust Logistics Process Automation (LPA) in manufacturing emerges as a crucial strategy for securing a leading position in the forthcoming landscape.

Transforming Manufacturing: Power of Logistics Process Automation

Efficiency and Speed

Logistics process automation simplifies a range of activities within the supply chain right from sourcing raw materials to delivering finalized goods. As a result, it accelerates order processing, decreases lead times, and enhances overall operational effectiveness in manufacturing.

Reduced Costs

Advanced logistics automation helps in optimizing inventory levels, reducing excess stock and stockouts, and improving resource utilization. This leads to cost savings in storage, carrying, and transportation.

Minimized Errors

Manual processes for logistics in the manufacturing sector is prone to errors and lead to production delays, quality issues, and inefficiencies. On the other hand, automation of logistics reduces human errors in data entry, order processing, and other tasks, leading to higher accuracy.

Improved Forecasting

LPA in manufacturing comes with data analysis and forecasting tools. This helps manufacturers to anticipate demand patterns more accurately and allows manufacturers to adjust production schedules and inventory levels accordingly.

Enhanced Visibility

Automated logistics solutions provide real-time visibility into supply chain operations. This allows manufacturers to track the movement of materials and products and respond promptly to changes or disruptions.

Optimized Production

Logistics automation can enhance the optimization of production scheduling and sequencing by considering variables like demand, resource availability, etc. This ensures efficient utilization of manufacturing equipment and labor.

Scalability

As manufacturing operations grow, LPA can help in the accommodation of increased volumes and decrease complexity without proportionally increasing manual labor. This leads to heightened resource utilization across the entire manufacturing facility.

Data-Driven Decision-Making

Logistics automation gathers and assesses data from diverse phases within the manufacturing process. These valuable data insights can be leveraged for ongoing enhancements and well-informed decision-making.

Better Customer Service

The implementation of logistics automation empowers manufacturers to offer real-time order tracking, precise delivery predictions, and effective management of customer inquiries. Together, they all result in elevated levels of customer satisfaction.

Complexities faced by the Manufacturing sector in Logistics Process Automation

Integration Complexity

Integrating automation technologies with existing legacy systems and processes can be complex. This also requires significant effort to ensure seamless communication and data exchange.

High Initial Investment

Implementing logistic automation technologies and software systems requires a substantial investment upfront. This might be a barrier for some manufacturers, especially MSME sectors.

Technical Issues and associated costs

Automation of logistics with in-house systems can experience technical glitches and breakdown issues. This will increase the manufacturer’s production cost as they need a dedicated team to handle technical glitches. Apart from that, the operational costs and specialized training costs will also increase.

Cybersecurity Concerns

As more processes become digitized and connected, the LPA in manufacturing becomes vulnerable to cyberattacks. This further necessitates robust cybersecurity measures to protect sensitive data and operations in the LPA process.

Process Complexity

LPA in manufacturing involves intricate processes with multiple variables. This makes it challenging to design and implement automated logistics solutions that can accommodate various scenarios and exceptions.

Supply Chain Variability

Fluctuations in demand, supply chain disruptions, and changes in market conditions can affect the effectiveness of LPA in manufacturing.

Regulatory Compliance

Adhering to industry regulations and standards while implementing LPA can be complex, particularly when automation affects quality control, safety, and compliance.

Initial Learning Curve

During the initial stages of logistics automation implementation, there might be a learning curve for employees and management to fully understand and utilize the new automated processes effectively.

Unpredictable ROI

While LPA in manufacturing promises increased efficiency and cost savings, achieving the expected return on investment (ROI) can sometimes be unpredictable due to various factors influencing production and market dynamics.

Transform Manufacturing Operations with FleetRobo’s LPA

FleetRobo’s Logistics Process Automation streamlines operations, leading to heightened efficiency and a notable positive influence on the manufacturing sector. FleetRobo’s LPA encompasses a range of components which caters to the unique requirements of manufacturing business use-case. Such as,

Integrated solution to reduce initial cost

FleetRobo’s LPA provides an integrated system that will not only be compatible with legacy systems but also will reduce the high initial cost required for placing such systems. With FleetRobo’s dedicated team, you don’t need to worry about the learning curve at all.

All this will help MSMEs or as a matter of fact, any manufacturing firm to create a competitive advantage and make a remarkable impression in the market space.

Enhanced Inbound Logistics Management

With our LPA in manufacturing, you can ensure systematic planning, coordination, and control of all activities. These can be related to the transportation, storage, and handling of raw materials, components, and other resources.

This can help you with proper supplier coordination, better inventory control, efficient transport planning, effective warehousing and storage, etc.

Automating Weighbridge Operations

FleetRobo’s LPA will automate weighbridge operation thereby efficiently helps in managing the weighing of incoming and outgoing raw materials, finished products, and other goods. This can play a crucial role in enhancing accuracy, speed, and data integration within the manufacturing supply chain.

Better Outbound Logistics Management

FleetRobo’s Logistics Process Automation in manufacturing facilitates systematic planning, coordination, and control of activities related to the transportation, distribution, and delivery of finished products from the manufacturing facility to customers or other consumption points. So that it can ensure products reach their intended destinations in a timely, cost-effective, and customer-satisfactory manner.

Seamless Integration with existing SAP solution

With LPA in manufacturing, you can seamlessly connect and align your various software applications, databases, and processes with the SAP software platform. This will help you with better data synchronization, efficient process alignment, better and streamlined workflow, etc.

Effortless e-way bill integration for automated billings

Our Logistics Process Automation solution will also integrate the GST e-way bill system for automated billings. This will not only ensure e-way bill generation but also ensure better compliance, avoid duplicity in the data entry process, efficient auditing mechanism, and faster TAT (Turn-Around-Time).

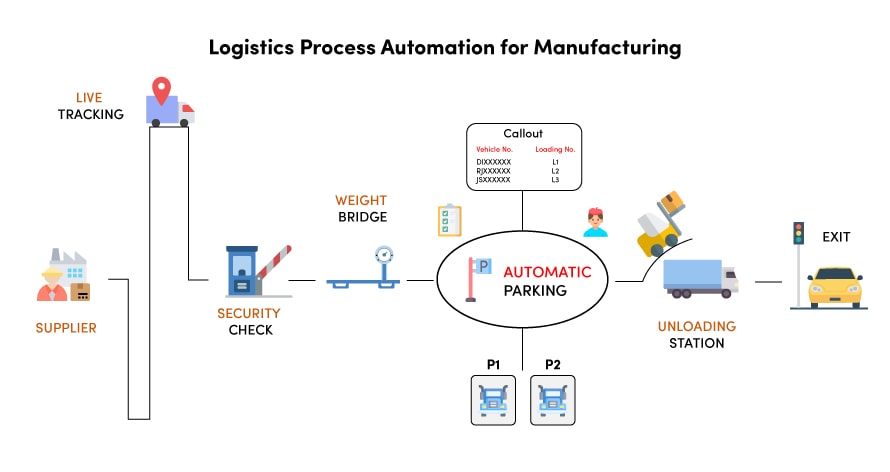

Efficient Parking Automation

This feature allows your fleet manager to efficiently manage the parking and storage of vehicles, trailers, and containers within the supply chain. Your manager will know the real-time availability of parking spaces thereby can provide better queue management and security, prioritizing delivery of goods and raw materials.

Intelligence-Driven Analytical Reports

Logistics automation will utilize data collected from different stages of the manufacturing process to uncover trends, patterns, correlations, and opportunities for optimization. So, implementing LPA in manufacturing will reduce expensive errors such as creating inaccurate forecasts, inaccurate logistics integration, etc.

Further LPA can improve the scalability of your manufacturing enterprise and aid in better data collection and integration. With FleetRobo’s LPA, one can get various reports on TAT improvement, weighbridge data, integration with MS Dynamics, etc. This can be used by your manager to undertake root cause analysis, trend, and predictive analytics of goods.

Conclusion

By incorporating FleetRobo’s Logistics Process Automation solution for your manufacturing industry, you can reap multitudes of benefits. Such as cost efficiency, reduce lead times, optimize inventory, enhance supply chain visibility, make informed decision-making, better market research and others. LPA in manufacturing marks a single stride toward enhancing your manufacturing operations.

FleetRobo offers a multitude of solutions to elevate your manufacturing excellence. FleetRobo’s GPS E-lock enables secure consignment locking and geofencing. FleetRobo’s fuel monitoring solution enhances fleet operational efficiency. Moreover, Consignment Tracking has the potential to revolutionize the current transportation efficiency within the manufacturing sector.