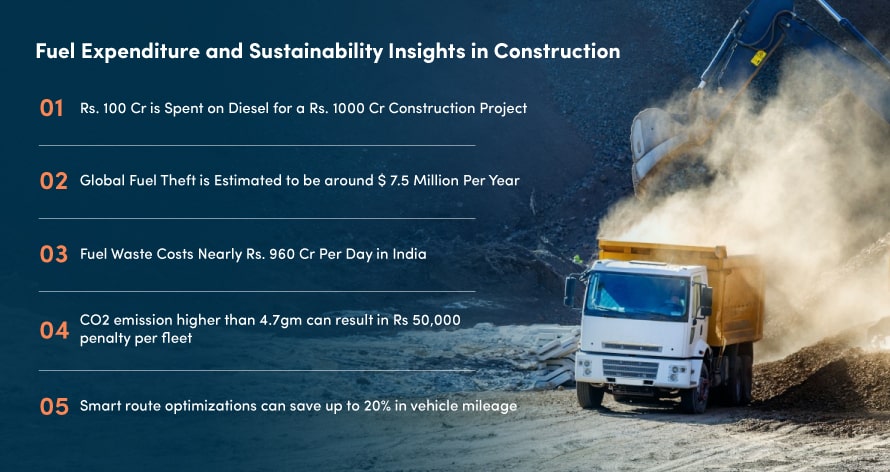

Fuel management is the most expensive part of construction businesses after labor costs. Most businesses in the construction and infrastructure sector face difficulties in efficiently managing their fuel expenditure. Fuel is costly and its price is increasing day by day. According to business-standard.com, for a road construction project of Rs 1000 Cr, around Rs 100Cr is spent on diesel. So, fuel tracking in the construction sector becomes more than a necessity.

Let’s understand the fuel monitoring system for construction and infrastructure sectors and see how it can assist business processes.

Table of Contents

- Significance of Fuel Tracking in Construction

- Fuel Management Challenges in Construction Space

- How Construction Sector Benefits from Fuel Tracking System?

- Conclusion

Significance of Fuel Tracking in Construction

Fuel tracking in the construction sector plays a crucial role in optimizing the fleet’s travel routes and carbon emissions. According to the International Energy Agency, the construction sector consumes 30% of the global final energy. And in addition to that it ranks third for global greenhouse gas (GHG) emissions.

Fuel tracking for the construction sector can help businesses achieve their sustainability goals in a streamlined and easy way. So, there’s a serious need for a fuel usage tracking solution. However, fuel management in the construction sector is not without its challenges.

Let’s look at some of the challenges construction businesses face, related to fuel management.

Fuel Management Challenges in Construction Space

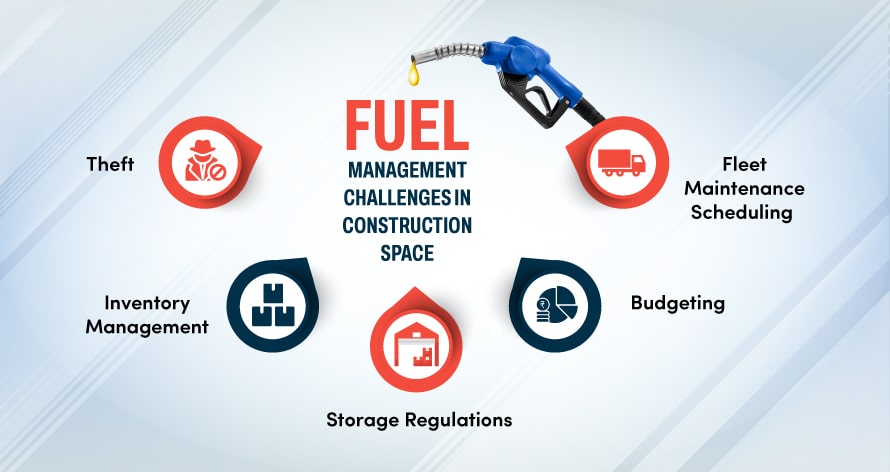

Theft

Construction sites are primarily vulnerable to fuel thefts due to the valuable and easily transportable nature of fuel. It can be carried out discreetly by employees, contractors, or even external thieves, making it easier for these individuals to go unnoticed while siphoning fuel. This raises the concern of implementing fuel tracking in the construction sector to prevent unauthorized access to fuel storage areas.

Info Insight: The average global cost of fuel theft in the construction sector is estimated to be around Rs. 6 billion ($7.5 million) per year.

Inventory Management

Maintaining a record of fuel inventory across different construction sites is challenging because of the varying demands and dynamic consumption patterns across different construction sites. In addition to that, issues related to record-keeping also lead to inefficient management of fuel inventory which can result in running out of fuel when needed.

Storage & Handling Regulations

Compliance with environmental and safety regulations for fuel storage and handling is complex. Construction companies need to invest in appropriate storage facilities to ensure adherence to local and federal regulations.

Budgeting & Cost Control

Due to unexpected fuel usage and inaccurate fuel records, managing fuel costs within a construction project’s budget becomes an issue. fuel tracking in the construction sector can help businesses remain up to date with fuel usage across different sites.

Fleet Maintenance Scheduling

Regular maintenance of equipment and vehicles is necessary for fuel efficiency. However, balancing maintenance schedules with project deadlines is a logistical challenge. This can easily be tackled with the mileage records of fleet vehicles.

How Construction Sector Benefits from Fuel Tracking System?

Construction companies heavily rely on heavy equipment like trucks, cranes, excavators, bulldozers, backhoes, etc. In addition, the prominent mode of fuel used in the infrastructure and construction space comes from diesel. So, fuel monitoring systems can help construction and infrastructure companies achieve significant cost savings, improved efficiency, better maintenance, and reduced environmental impact. Let’s get into the benefits of fuel tracking in the construction sector in detail to get a better understanding.

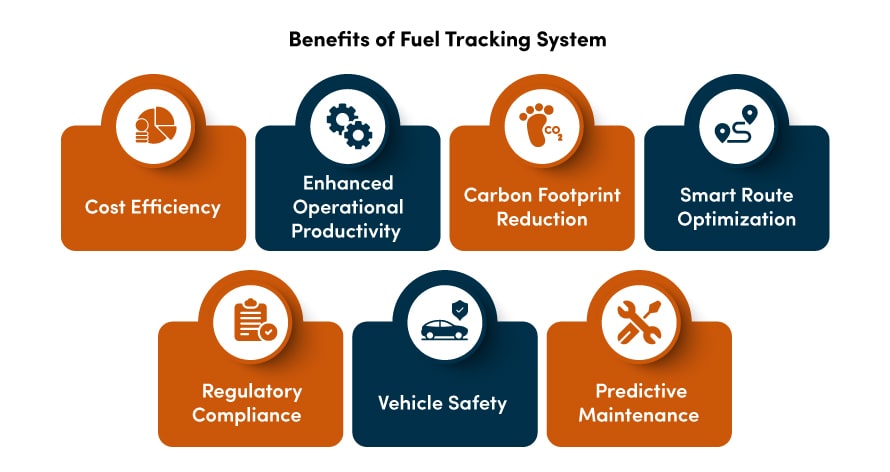

Improved Cost Efficiency

Fuel tracking for the construction sector provides insights into how machines and vehicles are consuming fuel. This way construction companies can reduce their fuel wastage, detect fuel theft, and promote efficient fuel usage.

Accurate fuel consumption data helps in budgeting and cost control. It allows construction companies to allocate resources more efficiently and reduce fuel-related expenses. In addition to that, understanding fuel usage patterns helps in better project planning. Companies can ensure that there is a sufficient fuel supply to meet project demands, preventing delays and interruptions.

FleetRobo’s fuel monitors varying depth fuel sensors can accurately detect fuel usage and give a detailed usage report for individual vehicles in real time. Moreover, the smart alert system with FleetRobo’s fuel monitoring solutions can instantly generate notifications for abnormal fuel usage. So, in case of potential fuel thefts, businesses can take swift actions with the fuel monitoring system.

Enhanced Operational Productivity

Fuel tracking in the construction sector can also help companies enhance operational productivity by providing real-time data on fuel consumption and vehicle performance. Companies can use this data to reduce idle time and improve their operational performance.

For example, A study conducted at Ahmedabad’s Swastik Intersection found that vehicles on average waste 63.53 liters of petrol and 33 liters of diesel every day at the intersection point. Here, FleetRobo’s fuel monitoring system offers idle engine tracking mechanism. So, whenever a vehicle remains still at a position with its engine turned on, the system keeps track of the fuel usage. And the GPS tracker transmits real-time location data.

Info Insight: Eliminating 4 hours of idling per day at Ahmedabad’s Swastik Intersection is expected to result in savings of approx. Rs. 9000.

Reduction in Carbon Footprint

Reducing carbon footprint by promoting sustainability and reducing greenhouse gas emissions. Fuel waste contributes to millions of tons of CO2 emissions and costs nearly Rs. 960 Crores per day in India, according to hindustantimes.com. So, using fuel tracking in the construction sector, businesses can optimize fuel usage and reduce fuel waste to significantly reduce their carbon emissions.

For example, FleetRobo’s fuel monitoring system gives detailed reports of the vehicle’s run-time along with its mileage reports. So, businesses can use this data to determine carbon emissions for specific vehicles and minimize their carbon footprint.

Info Insight: It’s projected that the global construction sector will still not achieve decarbonization by 2050.

Regulatory Compliance

Environmental regulations such as the Air (Prevention and Control of Pollution) Act, 1981 requires construction companies to monitor and report their fuel usage and emissions. And, if fleet CO2 emission is higher than 4.7gm, then penalty will be as high as Rs 50,000 per fleet, states an India Times article.

fuel tracking in the construction sector helps companies comply with these regulations to avoid penalties and fines. FleetRobo’s analytical reports help businesses get a detailed overview of all their vehicles from a single dashboard. So, in a single click, you can view idle time, mileage report, and fuel consumption report and generate a tabular view of this data for better analytics.

Route Optimizations

Construction vehicles are often big in size and are quite hard to maneuver quickly in case of potential diversions. In addition to that, if stuck in traffic the reporting time could be significantly extended. So, a fuel tracking system here can be used to optimize routes and enhance vehicle’s reporting and delivery times.

FleetRobo’s fuel tracking device is equipped with real-time GPS trackers. So, vehicle route from it start till its destination journey along with vehicle metrics is recorded in the backend. Construction companies can analyze this data and find an optimal route which aligns with their fleet goals (shortest route, minimal traffic, etc.).

Info Insight: According to Locus, route optimizations can save up to 20% in vehicle mileage.

Vehicle Safety

According to Indian Express, 71% of the cases reported in the last three years at the police department are of vehicle thefts. Though construction vehicles are difficult to steal, there still lingers around the possibility of theft. A good construction sector fuel monitoring system provides assurance of vehicle safety along with the ability to track fuel.

FleetRobo fuel monitoring solution comes with an inbuilt geofencing system. So, construction businesses can set predetermined area restrictions for the vehicles to go around. In case this geofence is breached, the system will generate instant alert. Moreover, with remote immobilizer functionality, businesses can effectively stop vehicle movement from a command center in case of vehicle theft.

Predictive Maintenance

A Nucleus Research study states that, when provided with predictive maintenance, vehicles have been found to reduce 35-50% and extend the assets’ lifespan by 20-40%. However, determining when a vehicle needs maintenance depends upon various factors like its uptime, traveled distance, mileage, etc. An optimal fuel tracking device collects all this information and helps businesses derive maintenance schedules.

FleetRobo’s fuel monitor reports display the mileage of vehicles for individual trips, uptime, traveled distance, time taken, and many other minute details. This data is displayed in the analytics dashboard both from the mobile device and command center. By scheduling maintenance based on actual usage and engine hours, companies can prolong the lifespan of their equipment.

Info Insight: Predictive maintenance can improve vehicle uptime by 9%.

Conclusion

Fuel tracking in the construction sector isn’t just a tool. It’s the secret weapon against fuel theft, inefficiency, and excessive costs. It’s the key to a greener, more profitable future.

So, as the construction sector continues to evolve and expand, don’t be left behind. Embrace the power of FleetRobo’s fuel monitoring today. And watch your business soar to new heights of efficiency, cost savings, and environmental responsibility.