Let’s set it straight. If automation in logistics is ignored, the challenges of manual logistics processes across the supply chain will lead to major inefficiencies — largely impacting the enterprise’s bottom line.

Indeed, most modern-day companies in logistics-hinged industries pledge high productivity and optimisation. However, their reliance on manual, defragmented, and paper-based logistic processes reveals significant operational challenges.

So, how can such logistics-intensive companies achieve the trifecta of efficiency, precision, and overall customer satisfaction? Moreover, how can these companies prepare themselves for the upcoming technological disruption across logistics?

Don’t sweat it. We have a one-stop solution for all your logistics process-related challenges. It’s called “Logistics Process Automation.” Let’s dive into the content to learn more about it, shall we?

TABLE OF CONTENT

- Logistics Process Automation: Antidote to Manual Logistics Processing

- Four major operational challenges of manual logistics processes

- Seven ways automation in logistics eliminates challenges of manual logistics processes

- Invest in FleetRobo’s one-stop logistics process automation solution

- Final thoughts on challenges of manual logistics processes

Logistics Process Automation: Antidote to Manual Logistics Processing

Logistics Process Automation or LPA is essentially the use of modern-day technology to monitor and manage the movement of goods inside a logistics facility.

The idea is to overcome the challenges of manual logistics processes through increased seamlessness, improved data alignment, and enhanced scalability. It facilitates improved supply chain performance from source (supplier) to destination (warehouse, customer, and distributor).

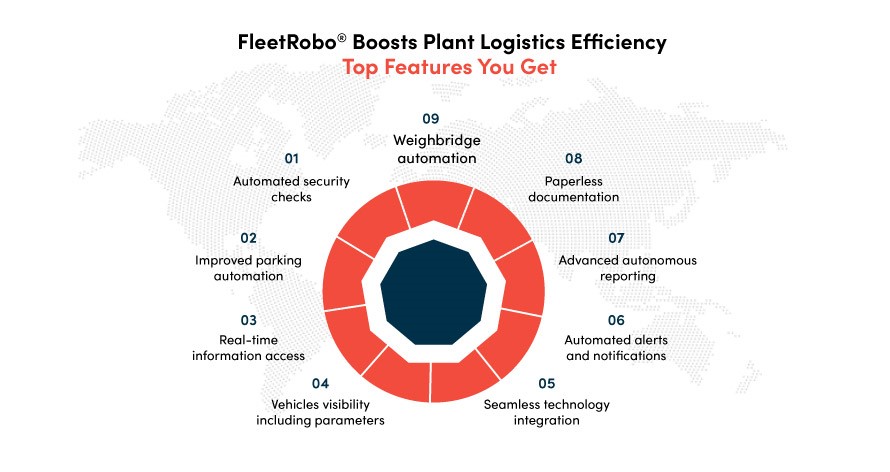

For example, the logistics process automation solution from FleetRobo helps improve and automate the following critical components of supply chain movement —

- Inbound logistics automation

- Security checks and risk compliance

- Weighbridge automation

- Truck parking automation

- Billing and invoicing

- Outbound logistics automation

No wonder solutions related to automation in logistics are expected to improve logistics efficiency by a staggering 87.5 percent by 2028.

But, before we discuss how logistics process automation solutions help eliminate the challenges of manual logistics processes, let’s discuss the major inadequacies of existing supply chain logistics.

Four major operational challenges of manual logistics processes

From the endless list of operational challenges, here we discuss the most important challenges of manual logistics processes. Without automation in logistics, a company experiences —

1. Invoicing related challenges of manual logistics processes

Although invoicing is a critical operation in any supply chain logistics process, the percentage of invoice errors occurring in existing systems is quite concerning.

Did you know the percentage of freight invoice errors lies between 15-66 percent?

Also, one in every four invoices gets rejected and sent for remediation — leading to delayed processing and TAT.

To sum up, manual invoicing is a resource-intensive proposal for modern-day logistics, leading to higher overhead costs.

2. Inefficient parking monitoring system

The parking issue pertains to a high volume of inbound and outbound trucks with consignments.

Ideally, companies depending on manual logistics supply chain monitoring hire a workforce to track the movement of trucks within the facility.

Regardless, truck drivers might make decisions at their discretion, which can cause bottlenecks and chaos at loading and unloading stations.

Remember, effective parking monitoring within the logistics facility is key to meeting the set TAT standards.

3. Manual processes are resource-intensive

As companies rely on paper-based logistics process monitoring, they need to hire more workforce to handle manual tracking.

This would result in managers having more time-intensive tasks cut out for them as they would need to track the workforce’s productivity.

Eventually, this would lead to an increase in overhead costs.

Moreover, hiring more people doesn’t necessarily result in higher productivity and efficiency.

4. Scalability-related challenges of manual logistics processes

With paper-driven logistics processes, a lack of technology integration is a given.

This is a challenge of manual logistics processes that, if not resolved, can significantly impact an organisation’s competency.

Not just technology integration, scalability can also link to plant expansion.

For example, a logistics facility eyeing overtime expansion will have to cater to more inbound and outbound vehicles, security checkpoints, and increased data alignment and management dependencies.

Technology-driven logistics processes, especially ones that are automation-focused, can prepare the company for scalability and technological disruptions.

Seven ways automation in logistics eliminates challenges of manual logistics processes

Logistics process automation is a proven solution that can effectively eliminate the challenges of manual logistics processes. Let’s learn how, shall we?

1. Automated security checks

Logistics automation software facilitates automated security checks.

This is possible through an AI-driven Automatic Number Plate Recognition (ANPR) system that ensures effective security checks, even in the most challenging working environments.

The system monitors trucks heading into a logistics facility. For example, FleetRobo’s ANPR checks for FASTag, valid sales orders for proper vehicle documentation and only allows valid vehicles into the facility.

Once the data collected matches the data already fed into the systems (through Sarathi and Vahan API), the security gates automatically open.

Thus, logistics process automation eliminates the need for manual security checks with the help of ANPR.

NOTE: Companies not looking forward to much capital investment can opt for application-controlled automated security systems. In this, companies can hand over mobile devices to their security guards, who will have the authority to open or close the gates upon inspection.

2. Weighbridge automation

LPA or logistics solutions resolve challenges related to manual cargo weight management. For example, inbound and outbound vehicles need to undergo a weighbridge to capture load information.

The overall weight of the vehicle, tare weight, net weight, gross weight, and associated tolerances are monitored by the ground-level workers and updated in FleetRobo’s centralised system.

The admin panel will have all the weight and tolerance-related information regarding the vehicles entering and exiting the weighbridge.

3. Parking automation

Parking is a major issue for a large percentage of logistics facilities since the parking areas are limited.

How does logistics process automation help automate parking or inbound logistics management? Systems with LPA leverage algorithms like FIFO to run the gating sequence.

Moreover, the sequences are supported through LED screens that provide logistics teams and drivers with parking-related information.

For example, FleetRobo uses the information gathered at the gate to monitor and automate the loading sequence (loading station and time) — eliminating congestion and bottlenecks at loading and unloading stations.

Furthermore, camera installation in the parking facility will provide admin and security guards with information related to available parking spaces. This will help automate the parking sequence and make real-time allocation-related decisions on the ground.

The best part is that supervisors will be able to access all these documentation-related checks on a mobile application, eliminating key challenges of manual logistics processes.

4. Real-time and easy information access for supervisors

Supervisors in a logistics facility need to have control over the supply chain process.

Logistics process automation solutions provide supervisors posted at loading and unloading bays, weighbridges, and security checkpoints with mobile apps that provide information about trucks ready to load or unload.

Based on the load information, supervisors can make decisions about the loading and unloading sequence. Moreover, the presence of speakers and LED screens in parking spaces facilitates information sharing.

NOTE: Supervisors can make decisions in real time, considering the nature of goods being loaded and unloaded.

5. Real-time visibility of vehicles including their various parameters

The mobile application not only provides information about trucks moving into the logistics facility but also about their current positioning.

The production manager will have complete visibility of the vehicles through the logistics automation software. Such real-time visibility also helps exit gate supervisors make the right decisions.

For example, trucks moving out of the logistics facility should have a valid exit pass, which can be generated and tracked automatically.

Besides, information related to outbound trucks will also be available on the mobile apps.

6. LPA helps with e-way bill generation

Did you know that logistics process automation solutions from FleetRobo can even automate billing and invoice generation? Let’s understand how.

Trucks, upon loading, move to the final billing station for e-way bill generation.

Here, one of the key challenges of manual logistics processes is dependency on several different applications and software to ensure proper billing.

However, FleetRobo, in conjunction with GSTRobo, can facilitate seamless invoice and e-way bill integrations.

At the same time, supervisors can use the LPA system to identify if billing is taking more or less time and where exactly the process delays happen.

7. Ensure seamless technology integration

Logistics process automation systems by FleetRobo provide adequate information for predictive and forecasting analysis.

This is possible through continuous and reliable tracking of all touchpoints within the supply chain.

Besides e-way bill generation, FleetRobo’s LPA can also seamlessly couple with GPS-tracking solutions for effective fleet visibility and management outside the plant.

The addition of the “Control Tower” to the LPA is another effective integration that ensures a more sophisticated monitoring system.

The entire quest to implement a logistics process automation solution will result in higher productivity, reliability, accessibility, and performance across the logistics facility.

Invest in FleetRobo’s one-stop logistics process automation solution

Now that you know how logistics process automation solutions from FleetRobo help, let’s list the major factors that keep companies from automating logistics processes in their existing workflows.

- Overwhelmed by technological disruption

- Reservations regarding budget and maintenance

- Misinformation about logistics automation

- Software’s ability to provide customised solutions

Logistics process automation experts at FleetRobo listen to your company-specific logistics requirements and provide a seamless solution for performance-oriented automation integration.

FleetRobo’s highly responsive team of logistics experts and professionals is known for providing next-generation, full-stack, and IoT-enabled telematics solutions.

These solutions ensure efficient tracking, monitoring, analysing, and reporting across web and mobile platforms — extending real-time intelligent reporting to performance-driven organisations.

Feel free to connect with us and we’d be happy to resolve all your logistics automation-related queries.

Final thoughts on challenges of manual logistics processes

Given the fierce competitiveness of the existing market landscape, an industry-wide automation-driven technological disruption is imminent.

Having said that, the onus of implementing automation in logistics lies with the supply chain and operational heads of companies, especially the ones that still rely on manual, paper-based, and defragmented logistics processes.

While solutions from FleetRobo can effectively overcome the challenges of manual logistics processes, it is the responsibility of the organisational heads to make their companies automation-ready.

In other words, purposeful employee training is necessary to squeeze the most out of logistics process automation solutions.

Such an all-around approach to logistics process automation is bound to produce significant results and help enterprises achieve the set productivity and profitability goals.

Most importantly, you will set your company up for increased efficiency across in-facility logistics processes. Did you find this post helpful? Stay tuned for more informative posts on the challenges of manual logistics processes in the future.