Vehicle verification at gate-in/gate-out stations is the first and last process in any logistics facility. Therefore, every second spent in the process matters and should be accounted for when running an efficient and performance-oriented logistics operation. This is why you should know the challenges of manual vehicle verification in existing inbound and outbound logistics processes.

We keep coming across companies that largely rely on manual vehicle verification processes that are well-documented for their inefficiencies and are prone to errors. Despite the widespread implementation of boom barrier automation, companies in India still employ supervisors and managers to run vehicle verification.

TABLE OF CONTENT

Logistics facilities across India cater to hundreds and sometimes even thousands of trucks coming in and going out every day. Trucks are let in and let out at boom barrier stations only if the information they carry matches with that stored in the facility’s system. In other words, logistics facilities track the entry and exit of vehicles with the help of information manually collected at boom barrier stations.

Manual vehicle gate-in and gate-out process

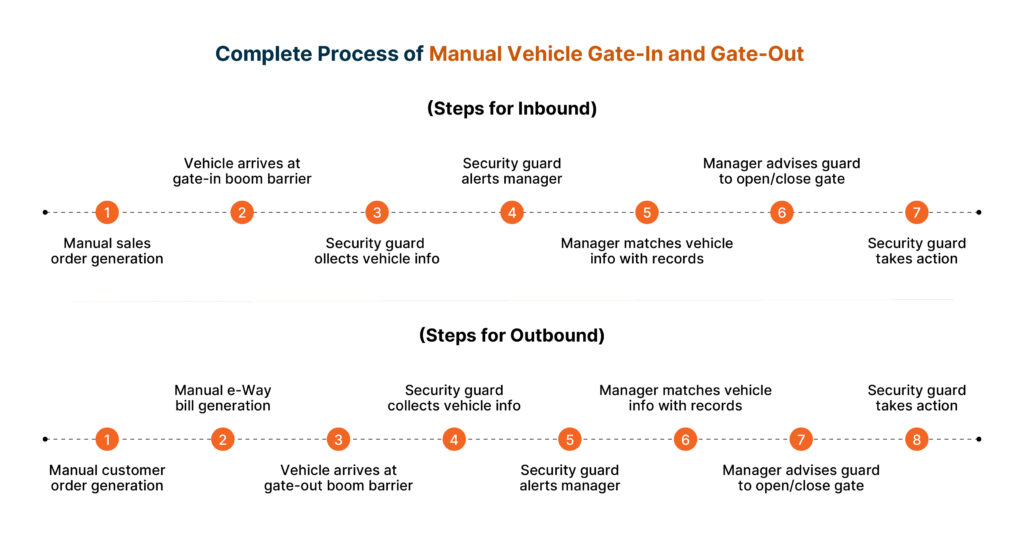

Now, considering the importance of the gate-in and gate-out processes, logistics companies hire supervisors to handle vehicle verification. However inefficient, here’s how the process works —

Upon arriving at the boom barriers a security guard collects the vehicle information like sales order, consignment-related details, vehicle registration, driver details, and other critical data points.

The guard then connects with the supervisor or manager handling the logistics operation and passes on the information. The decision to let in the vehicle stays with the guards in case the manager already shared the details with them.

However, the supervisor’s responsibility is to manually check if the details collected are correct and verify whether or not the details match the information mentioned in the records. The supervisor advises the guard to open the boom barrier only if the details match.

As you can see, the entire manual gate-in/gate-out process is subject to the availability of security guards and managers.

If one of them is unavailable, it will result in delays and productivity-related issues. Not only that, the process depends on communication channels, and correct recording of data (register maintenance) — all this while ensuring there is no conflict of interest.

Challenges of manual vehicle verification and gate management

This brings us to discussing the existing and potential challenges of manual vehicle verification during the gate-in/gate-out process. Here are key problems associated with manned vehicle verification —

1. High turn-around time

The countdown starts right from when a vehicle enters the logistics facility and exits it. However, a manned vehicle verification process takes time at both ends, leading to a higher turn-around time.

2. Requires more steps to complete

The steps required to perform manual vehicle verification are comparatively more than automated verification. This is because there are several elements involved such as boom barrier station supervisor, manager, manual registers, and more. This goes on to lengthening a simple process.

3. More effort, lower efficiency

The collective effort required to effectively perform vehicle verification at gate-in/gate-out stations is high. At the same time, the boom barrier station supervisor or guard has many other duties besides manning the boom barrier, for example, eliminating vehicle congestion, preventing unauthorised entries, and more. Such distracted focus leads to lower logistics efficiency.

4. Increases overhead costs

As a manual vehicle verification process requires more people, the logistics facilities will have to spend a chunk of their limited budget on training the guards and managers. This can cause significant downtime as it takes time to get used to the manual vehicle verification processes. You will need resources to manage the physical records and receipts, which eventually leads to higher overhead costs.

5. Prone to human errors

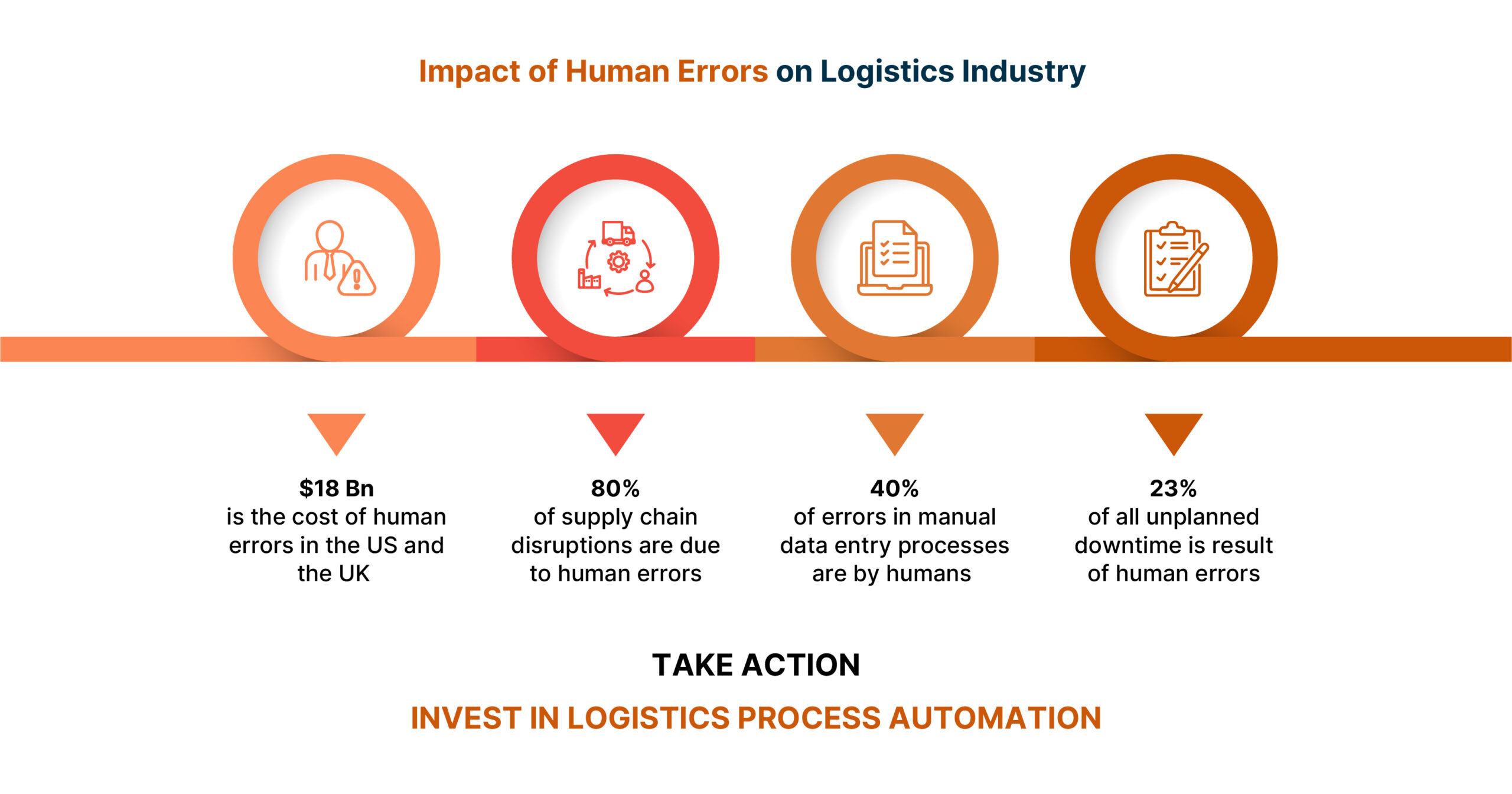

Did you know more than 80 percent of supply chain disruptions are the result of human errors? The more people involved in the vehicle verification process, the higher the chances of human errors. In manual vehicle verification, we have several humans working together at gate-in/gate-out stations, which is bound to lead to more human errors.

6. Open to frauds

The boom barrier station supervisors at gate-in/gate-out stations have direct access to the vehicles. In case there is a conflict of interests, the supervisors can cause fraud that will eventually impact the logistics facility’s bottom line. Most importantly, it will lead to customer dissatisfaction.

7. Higher vehicle idle time

The longer the vehicle verification process, the higher the vehicle idle time. To improve logistics facility efficiency, incoming vehicles must be minimally subject to short halts to reduce vehicle idling and driver alighting.

8. Not green or sustainable

One of the major challenges of manual vehicle verification processes is that it is entirely run through paper-based documentation and monitoring. Delays in the manual process also result in increased vehicle idling and pollution. This leads to an increase in carbon footprint, which goes against the recent trend of establishing greener and more sustainable logistics facilities.

9. Makes scaling difficult

As you venture with more and more companies and look for plant expansion, your logistics facility will experience a surge in vehicles coming in. This will lead to a need for quicker and more stringent vehicle verification processes, something manual boom barrier stations are unable to provide.

Automated vehicle verification process in logistics

We discussed how lengthy, resource-intensive, and error-stricken manual vehicle verification processes can be. Does automated vehicle verification during the gate-in/gate-out process provide an efficient alternative? Let’s find out.

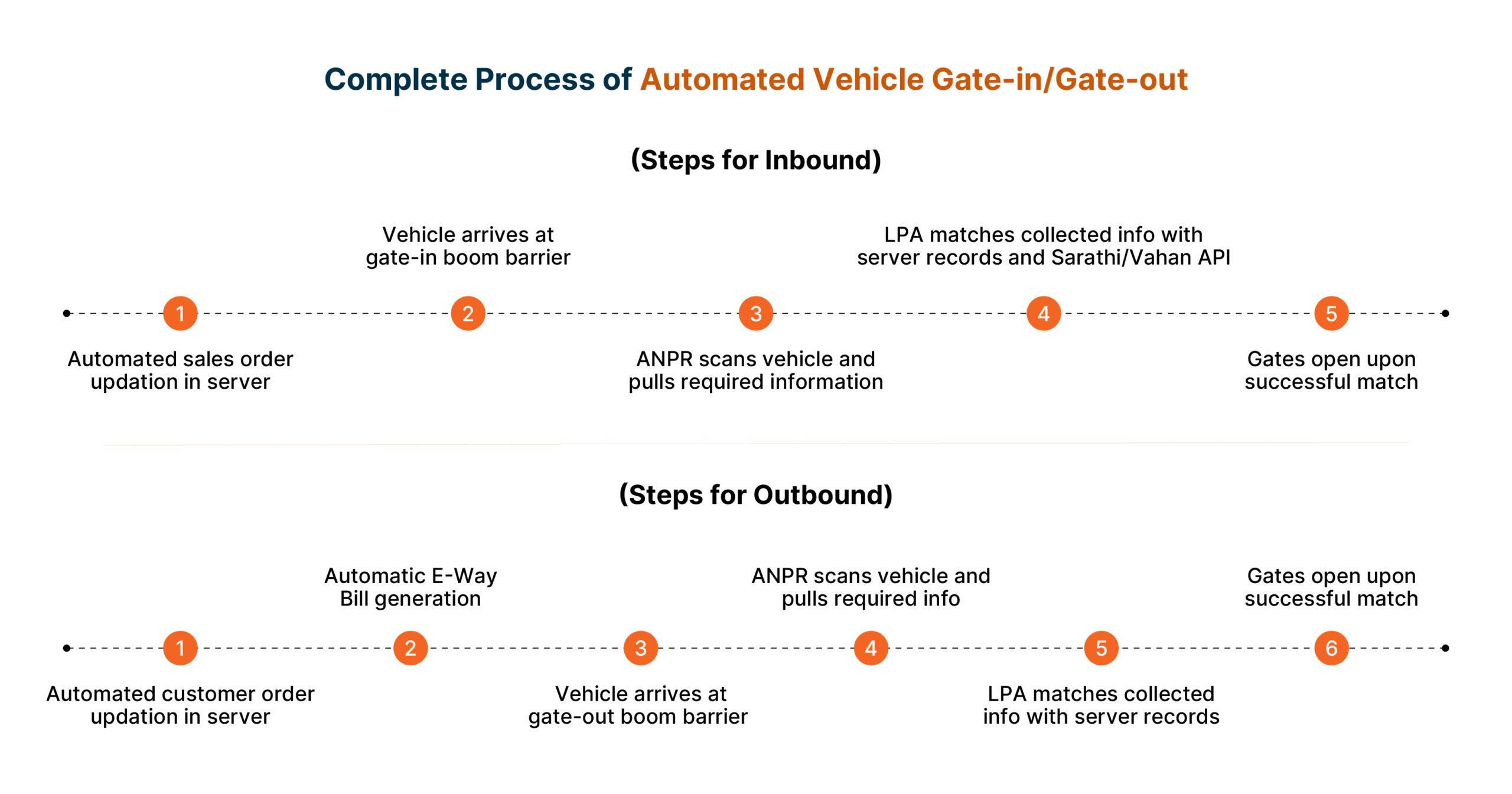

In an automated gate-in/gate-out station, the vehicle verification process starts the moment a vehicle stops at the boom barrier. The ANPR (Automated Number Plate Recognition) system scans the vehicle’s number plate and matches it with the records stored on the server with the help of Sarathi and Vahan API.

If the collected information matches the records, the boom barrier automatically opens and the vehicle is let in. The same process happens during gate-out as the vehicle information is matched with the gate-out sequence and customer order, in addition to automated e-Way bill integration.

In this way, automated vehicle verification during the gate-in/gate-out process eliminates the need for station supervisors — one of the major challenges of manual vehicle verification. The process is completely automated with the help of the ANPR system, a critical element of our logistics process automation solution.

How logistics process automation overcomes the challenges of manual vehicle verification?

But we have only touched the tip of the iceberg when it comes to discussing the benefits of automated gate management. Here are some of the most important advantages of implementing automated vehicle verification against manual vehicle verification —

| MANUAL Vehicle Verification Process | AUTOMATED Vehicle Verification Process |

| Depends on — 1. Security guard availability 2. Manager availability 3. Communication channel 4. Correct recording of data 5. No conflict of interests | Depends on — 1. Cloud Data Generation 2. ANPR functionality 3. Server availability |

| Large number of manual steps | Completely automated |

| Inefficient gate-in/gate-out monitoring | Real-time monitoring available |

| Leads to fraud and theft | Improves accountability |

| Collects only a few data points | Detailed gate entry/exit logs |

| Paper-based register management | Automated register management |

| Errors and unavailability can lead to delays | No delays due to automation |

| Long process results in high TAT | Quick turn-around time |

| Unauthorised entry can happen | Prevents unauthorised entry |

| Higher vehicle idling time | Lower vehicle idling time |

| Prone to health and safety risks | Caters to health and safety standards |

| No reports generation | Automated reports to provide insights |

| Higher overhead costs | One-time investment, minimum maintenance |

Read more — Quit Manual Processes: Achieve 20% Higher Efficiency with Logistics Process Automation

Invest in Logistics Process Automation solution

Now that you are well-acquainted with the challenges of manual vehicle verification and how automated vehicle verification benefits logistical operations, it’s time to plan how you will implement automated gate-in/gate-out processes.

If you are willing to invest in automated vehicle verification, you should consider our logistics process automation solution. This is because we provide real-time monitoring of stations, automated security checks, real-time vehicle visibility, seamless information access, automated reports, and many other key integrations.

Here are some key benefits of our Logistics Process Automation solution —

- Automated security checks

- Improved parking automation

- Real-time information access

- Vehicle visibility including parameters

- Seamless technology integration

- Automated alerts and notifications

- Advanced autonomous reporting

- Paperless documentation

- Weighbridge automation

What are you waiting for? Connect with our logistics process automation expert and we’ll help you install an automated vehicle verification system across the gate-in/gate-out stations in your facility. Stay tuned for more informative posts in the future.